Bound Box

Redesigning Encaja's reusable wooden shipping crates. The new elastic staple eliminates the use of tools, prevents wood damage, and won sustainability and young design awards.

Redesigning Encaja's reusable wooden shipping crates. The new elastic staple eliminates the use of tools, prevents wood damage, and won sustainability and young design awards.

Year

2023

Client

Encaja

Project

Packaging Design

Overview

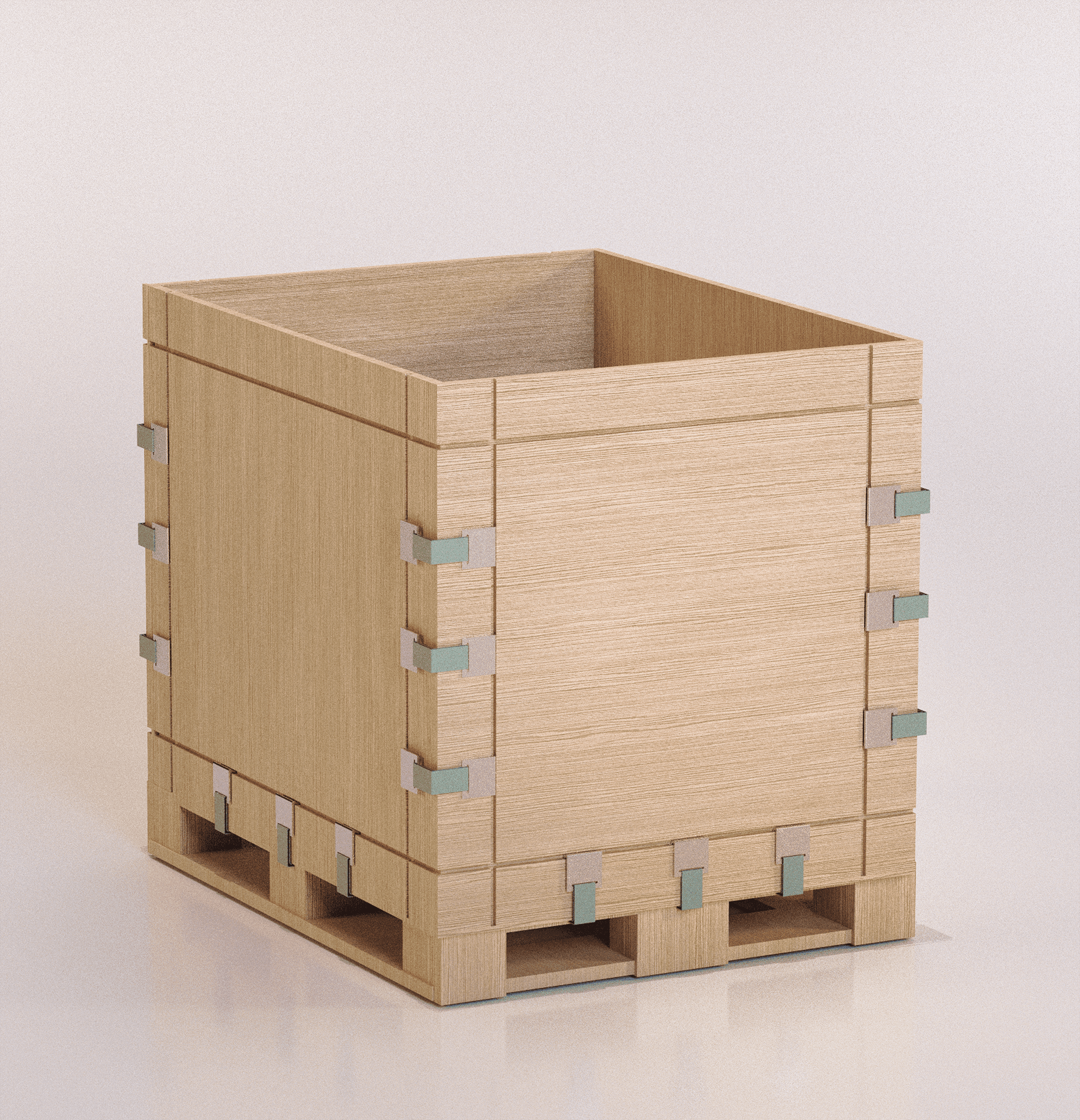

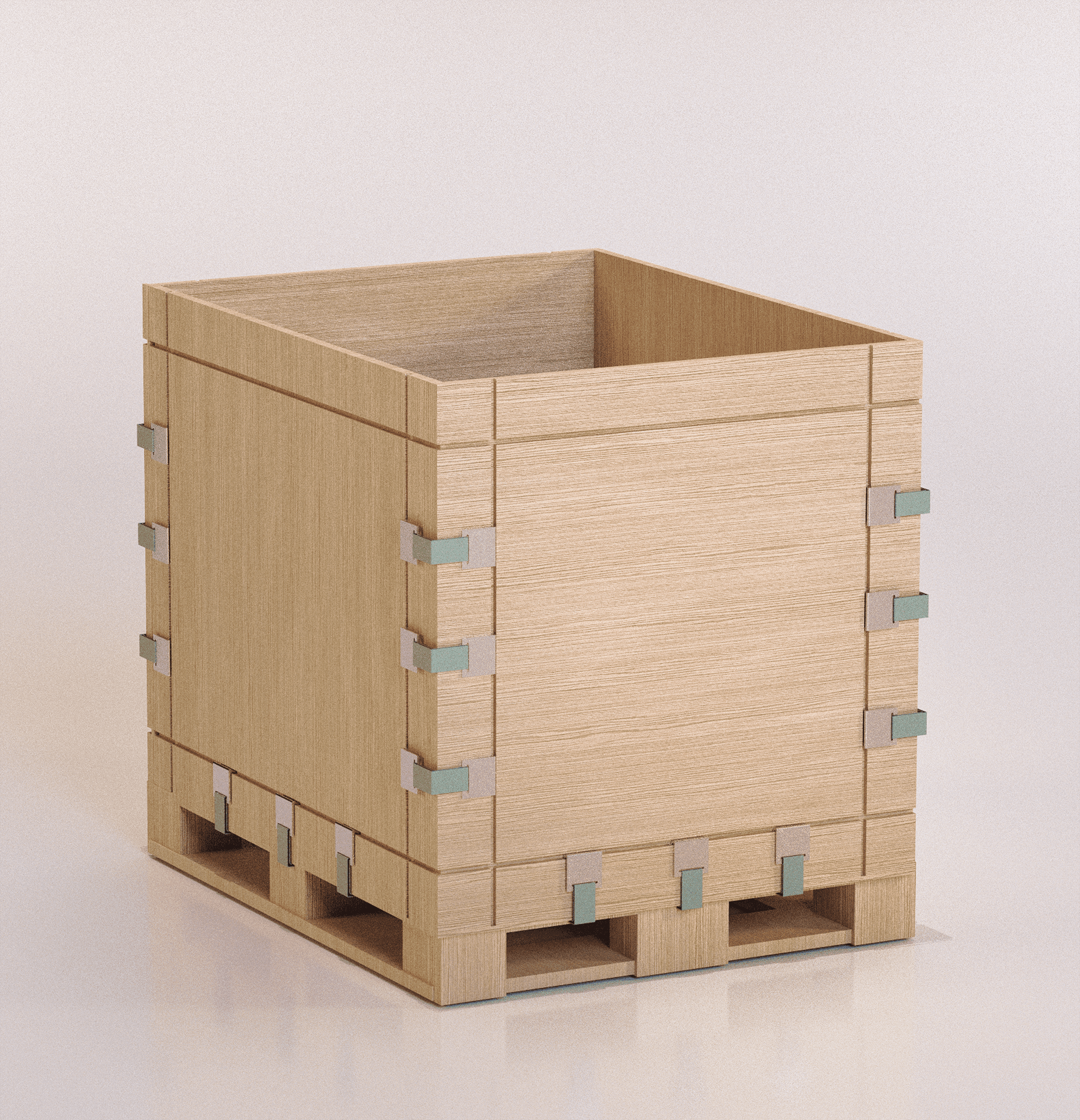

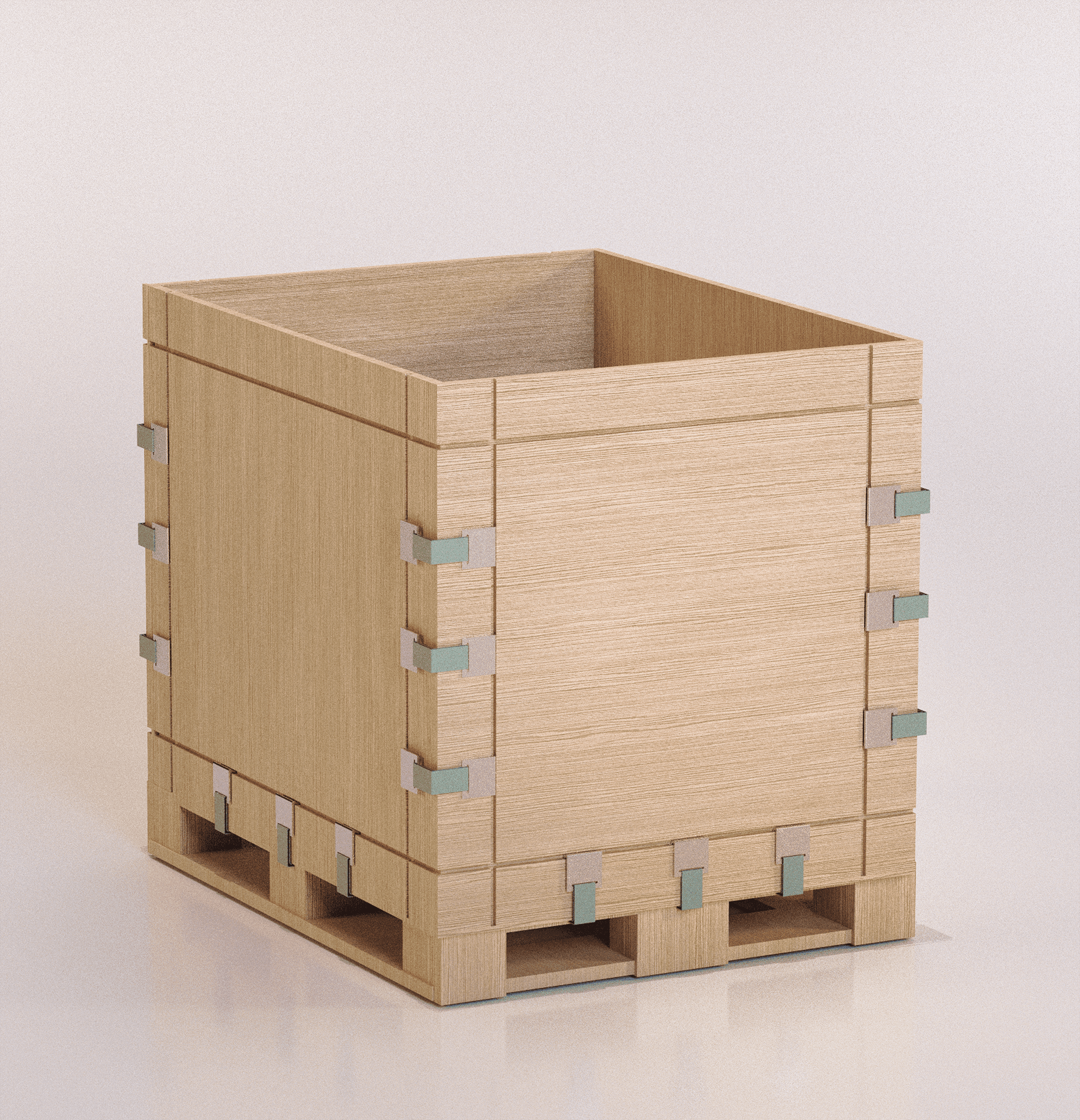

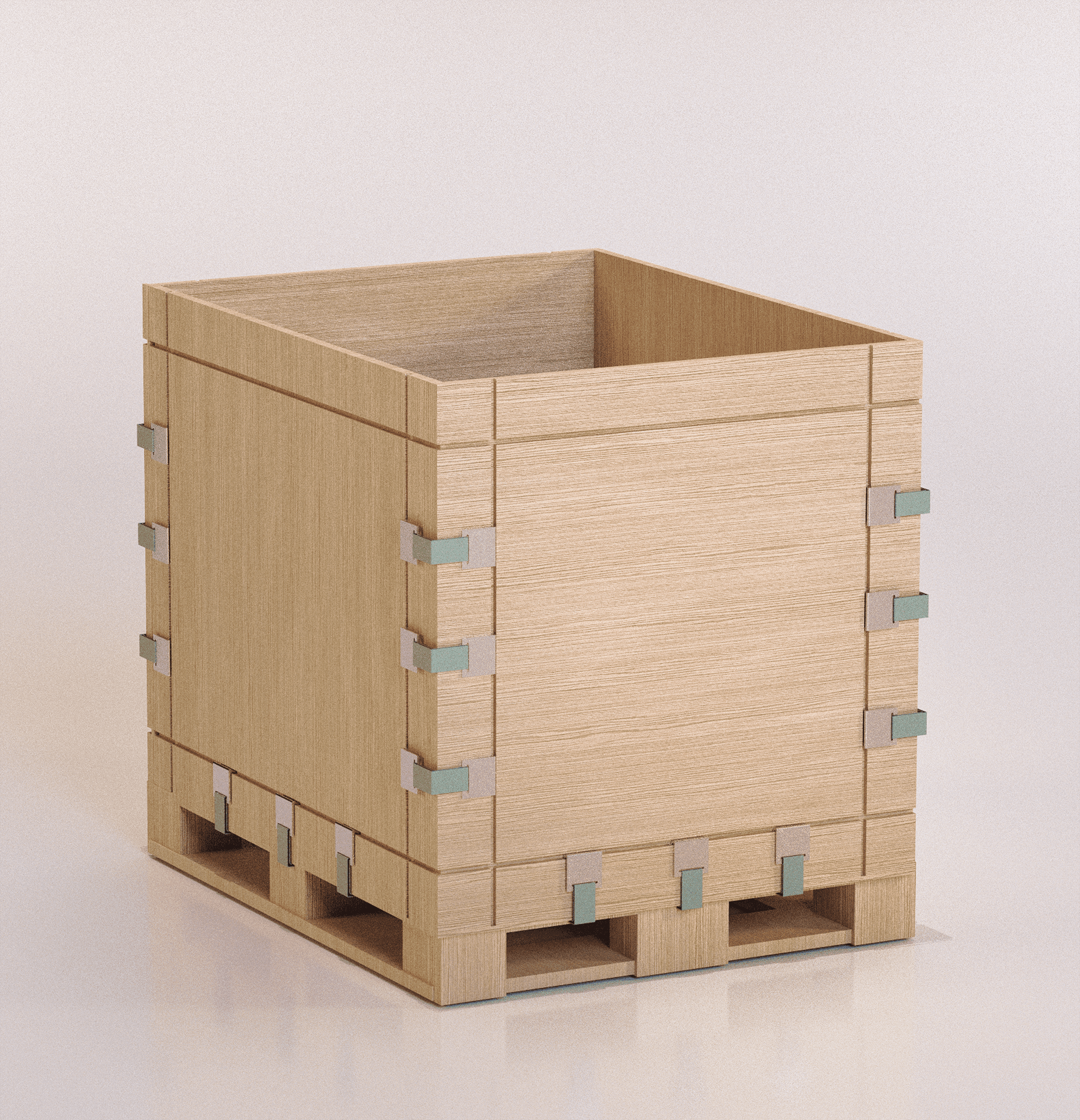

Encaja’s Bound Box is a reusable wooden shipping crate used across industries. The system works well except for one part: the metal staples that hold the boards together. Every time workers disassemble a crate, they need and external tool to remove the staples. This damages the wood grooves, shortens the crate’s lifespan, and the loose staples have nowhere to go when storing flat-packed boards.

The final design replaces rigid metal with elastic staples. Two stainless steel ends connected by a natural rubber band. The staple stretches to place and remove without tools, doesn’t damage the wood grooves, and wraps around stacked boards for a compact storage solution.

Encaja’s Bound Box is a reusable wooden shipping crate used across industries. The system works well except for one part: the metal staples that hold the boards together. Every time workers disassemble a crate, they need and external tool to remove the staples. This damages the wood grooves, shortens the crate’s lifespan, and the loose staples have nowhere to go when storing flat-packed boards.

The final design replaces rigid metal with elastic staples. Two stainless steel ends connected by a natural rubber band. The staple stretches to place and remove without tools, doesn’t damage the wood grooves, and wraps around stacked boards for a compact storage solution.

Encaja’s Bound Box is a reusable wooden shipping crate used across industries. The system works well except for one part: the metal staples that hold the boards together. Every time workers disassemble a crate, they need and external tool to remove the staples. This damages the wood grooves, shortens the crate’s lifespan, and the loose staples have nowhere to go when storing flat-packed boards.

The final design replaces rigid metal with elastic staples. Two stainless steel ends connected by a natural rubber band. The staple stretches to place and remove without tools, doesn’t damage the wood grooves, and wraps around stacked boards for a compact storage solution.

Encaja’s Bound Box is a reusable wooden shipping crate used across industries. The system works well except for one part: the metal staples that hold the boards together. Every time workers disassemble a crate, they need and external tool to remove the staples. This damages the wood grooves, shortens the crate’s lifespan, and the loose staples have nowhere to go when storing flat-packed boards.

The final design replaces rigid metal with elastic staples. Two stainless steel ends connected by a natural rubber band. The staple stretches to place and remove without tools, doesn’t damage the wood grooves, and wraps around stacked boards for a compact storage solution.

The Result

After prototyping we refined dimensions, angles, and materials into a production-ready design that Encaja could manufacture.

After prototyping we refined dimensions, angles, and materials into a production-ready design that Encaja could manufacture.

After prototyping we refined dimensions, angles, and materials into a production-ready design that Encaja could manufacture.

After prototyping we refined dimensions, angles, and materials into a production-ready design that Encaja could manufacture.

Enboxing

There are three components that keep the box together: two stainless steel ends and one natural rubber band. Steel ends are shaped at 60° to grip the wood grooves of the panels. For assembly, simply stretch the staple, place both ends in grooves and release. Even easier to disassembly: pull to stretch and lift out. Since workers don't need tools to remove the staple, the wooden boards stay intact throughout the process.

Flexible enough to install,

strong enough to secure.

Packing it up

The staple's flexibility allows it to hold boards when crates are empty. Staples wrap around the board stack, grouping everything into one unit. This solves another issue: staples won't get lost when boxes are transported empty. Impact

Learnings

The prototyping phase taught me the most. Sketches can show anything, but making something that actually works requires constant iteration and testing. I learned that the gap between concept and execution is where the real design work happens, and sometimes you just have to keep building until it works.

The project received recognition at two major packaging awards: the Sustainability Award from the Cluster de Envase y Embalaje and the Young Design Award at Liderpack. Thanks to these, we were also nominated for The Global Packaging Awards: The WorldStar Competition.

The prototyping phase taught me the most. Sketches can show anything, but making something that actually works requires constant iteration and testing. I learned that the gap between concept and execution is where the real design work happens, and sometimes you just have to keep building until it works.

The project received recognition at two major packaging awards: the Sustainability Award from the Cluster de Envase y Embalaje and the Young Design Award at Liderpack. Thanks to these, we were also nominated for The Global Packaging Awards: The WorldStar Competition.

The prototyping phase taught me the most. Sketches can show anything, but making something that actually works requires constant iteration and testing. I learned that the gap between concept and execution is where the real design work happens, and sometimes you just have to keep building until it works.

The project received recognition at two major packaging awards: the Sustainability Award from the Cluster de Envase y Embalaje and the Young Design Award at Liderpack. Thanks to these, we were also nominated for The Global Packaging Awards: The WorldStar Competition.

The prototyping phase taught me the most. Sketches can show anything, but making something that actually works requires constant iteration and testing. I learned that the gap between concept and execution is where the real design work happens, and sometimes you just have to keep building until it works.

The project received recognition at two major packaging awards: the Sustainability Award from the Cluster de Envase y Embalaje and the Young Design Award at Liderpack. Thanks to these, we were also nominated for The Global Packaging Awards: The WorldStar Competition.

other projects

Cabinet

Cabinet

Cabinet

View Project

View Project

View Project

View Project

View Project

View Project

UX/UI + Graphic Design

Universidad Complutense de Madrid

Cabinet

Cabinet

Cabinet

View Project

View Project

View Project

View Project

View Project

View Project

UX/UI + Graphic Design

Cabinet

Cabinet

Cabinet

View Project

View Project

View Project

View Project

View Project

View Project

UX/UI + Graphic Design

Universidad Complutense de Madrid

Cabinet

Cabinet

Cabinet

View Project

View Project

View Project

View Project

View Project

View Project

UX/UI + Graphic Design

Universidad Complutense de Madrid

Postcards Aboard

Postcards Aboard

Postcards Aboard

View Project

View Project

View Project

View Project

View Project

View Project

Interaction Design

Musealia Exhibitions & Museums

Postcards Aboard

Postcards Aboard

Postcards Aboard

View Project

View Project

View Project

View Project

View Project

View Project

Interaction Design

Postcards Aboard

Postcards Aboard

Postcards Aboard

View Project

View Project

View Project

View Project

View Project

View Project

Interaction Design

Musealia Exhibitions & Museums

Postcards Aboard

Postcards Aboard

Postcards Aboard

View Project

View Project

View Project

View Project

View Project

View Project

Interaction Design

Musealia Exhibitions & Museums